The strength of ITALFIL S.p.A. lies in the quality of its products, achieved through a continuous search for solutions that offer the best in the welding industry while maintaining the flexibility to meet the diverse needs of our customers.

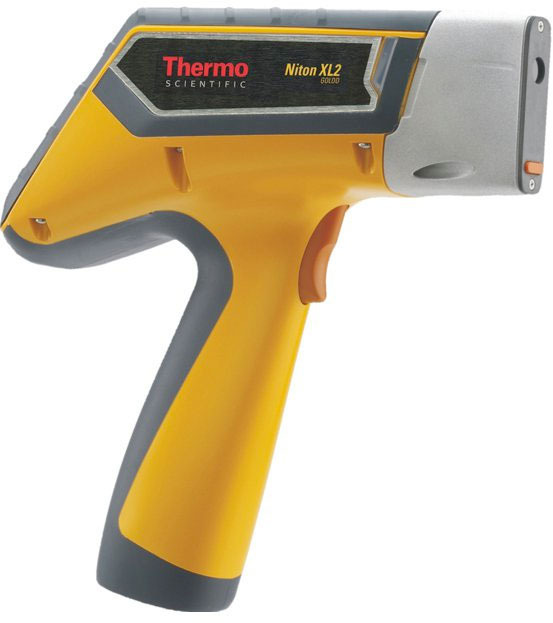

In recent years, significant investments have been made in our laboratory, research and development activities. This includes the acquisition of advanced technological equipment and the hiring of specialized technical personnel.

Every stage of production, from the receipt of raw materials to the packaging of the finished product, is closely monitored with strict quality controls to ensure precise working parameters and deliver a product that is consistently reliable and of the highest quality.

Anti-mix-up tests are carried out on heats and lots throughout all manufacturing steps, and automatic welding tests are performed on the wires to monitor and verify the quality of the welding consumables.

This approach has enabled ITALFIL S.p.A. not only to obtain ISO 9001:2015 certification and Factory Production Control certification for CE/UKCA marking for use in civil construction within the European Union, but also to achieve numerous product approvals from prestigious certification bodies such as TUV, DB, CWB, LR, DNV, RINA and NAKS.

ITALFIL S.p.A. | P. I. 01000530285

Realizzato da Axera Web & Digital | Privacy e cookie policy