The NEW WIRE range has been developed to meet the increasingly demanding quality requirements of today’s welding industry. These requirements include continuous improvements in welding performance, reductions in maintenance and downtime, and ensuring the highest weld quality. ITALFIL S.p.A., leveraging its expertise and experience in innovating both processing technologies and raw materials, has created an innovative product that satisfies even the most exacting customer demands.

REQUEST INFORMATIONS

The final result is a new-generation bare, uncoppered wire, produced through an innovative combination of the NEW WIRE process – a dry drawing of the wire to its final diameter – and carefully selected additives, which provide the NEW WIRE range with excellent properties previously unmatched in conventional MIG/MAG welding wires.

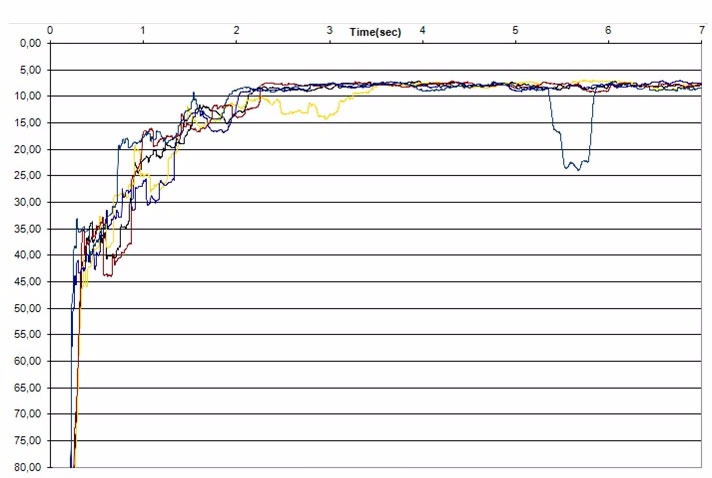

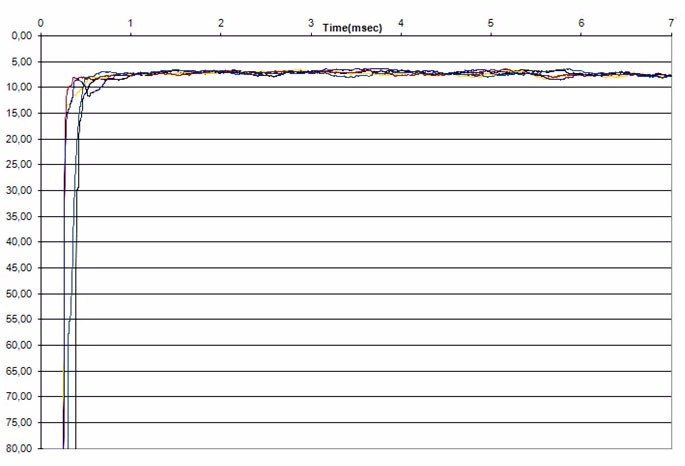

Tests conducted on NEW WIRE show extremely rapid arc ignition and arc stability achieved in less than 1 millisecond. The diagrams beside illustrate a comparison: a high-quality standard wire is shown at the top, while the NEW WIRE is at the bottom. The NEW WIRE stabilises much faster, and subsequent fluctuations are minimal and almost imperceptible.

Stick-out (the distance from the nozzle to the workpiece) remains constant, preventing the wire from sticking to the nozzle during prolonged welding and avoiding interruptions in the welding process.

Exceptional conduit sliding, very low vibrations and minimal wire feed effort across a wide range of welding parameters ensure minimal material loss. These properties are particularly beneficial in applications with long or highly curved conduits, as well as in robotic and automated welding systems.

NEW WIRE ensures a significant reduction in spatter and its size, as well as minimal silicate formation on the weld bead, resulting in an excellent aesthetic finish.

Thanks to these exceptional properties, NEW WIRE can, in some applications, replace flux-cored wires. With NEW WIRE 2, high impact strength values have been achieved down to -50°C when using CO2 gas.

Similar to the EVO wire range, NEW WIRE also reduces fume emissions during welding, helping to protect the health of operators.

UPON REQUEST, A TECHNICAL DOCUMENT CAN BE PROVIDED WHICH ILLUSTRATES THE ADVANTAGES OF NEW WIRES IN VERY DETAILED MANNER.

For further information, contact the sales office or go to the "contacts" section of the website.

ITALFIL S.p.A. | P. I. 01000530285

Realizzato da Axera Web & Digital | Privacy e cookie policy